To effectively protect electrical wires from corrosion damage, it is important to understand the differences between PVC coated conduit and PVC conduit systems. This includes how and where they are used for corrosion protection, as well as individual features and installation techniques.

Rigid Poly Vinyl Chloride (PVC) Conduit

Rigid PVC conduit is lightweight and made from a combination of plastic and vinyl. PVC conduit is commonly used in residential, commercial and utility applications.

Two thicknesses are available – Schedule 40 and Schedule 80. Schedule 80 has a thicker wall and is the same outside diameter as Schedule 40. This makes the inside diameter of the Schedule 80 more narrow. The same fittings are used for both Schedule 40 and 80.

PVC conduit can be installed above ground and below grade due to its resistance characteristics to corrosion. However, PVC conduit is nonconductive and is not supplied with threads.

Installation of Rigid PVC Conduit:

Because PVC conduit is not threaded, connections must be sealed using liquid glue. Measure carefully to avoid dry fitting your connections, as PVC conduit and fittings can be difficult to pull apart once they have been glued together. Also, since PVC is not conductive, a ground wire is always needed when using PVC electrical conduit.

To bend PVC conduit, heat it with a portable heat box or heat blanket.

The best wire choice for PVC conduit is THHN (Thermoplastic High Heat-resistant Nylon-coated). Stranded THHN is used on most commercial jobs. It is more flexible than solid wire and is easier to pull through PVC conduit and does not spring back when pushed into the electrical box. Other types of wire have a sticky rubber sheathing that makes it difficult to pull through PVC conduit.

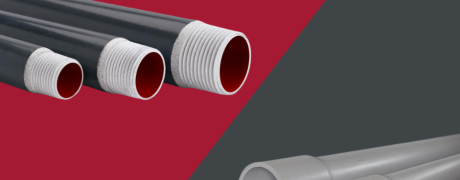

PVC Coated Conduit

PVC coated conduit offers long-term reliability and protection for electrical raceways in harsh locations. PVC coated conduit is made of rigid steel or aluminum rigid metal conduit. It is coated in a 40-mil grey PVC exterior coating with a 2-mil urethane interior coating. The PVC coated conduit protects conductors from mechanical damage and costly corrosive attacks by combining the strength of the metal base and the corrosion protection of the PVC. PVC coated conduit is ideal for use in a range of infrastructure, industrial and commercial applications. It is particularly effective in corrosive and harsh environments.

It is threaded and securely joined using coated couplings. This ensures that electrical continuity is maintained across assembled joints. PVC coated conduit is conveniently available in 10’ nominal lengths. While PVC coated steel is the most widely used, PVC coated aluminum is a good option when weight is a consideration,

Installation of PVC Coated Conduit:

Installation of PVC coated conduit requires specific tools to accommodate the coating and keep it free from damage. Hand tools can be bought directly from the manufacturer, and shoes for bending can be purchased from any bending machine manufacturer. Factory-bent elbows are also available for purchase.

PVC sleeves on conduit couplings and fittings help isolated corrosives from the threads at the joints and should not be removed. Any wire type can be used with PVC coated conduit as it has advantages during wire pulling, including low coefficient of friction and protection against burn through.

To ensure the best possible PVC coated conduit installation, it is recommended that installers be certified. This training is available free of charge from the manufacturer. The course includes classroom and hands-on instruction encompassing proper installation techniques and tools. It also covers hands-on instruction for clamping, cutting, threading, bending and assembly, along with an interactive discussion of techniques and troubleshooting.

What is The difference?

PVC COATED CONDUIT

- Metallic

- Made from steel or aluminum with PVC coating

- Installed/connected using coated coupling

Features/Benefits:

- Mechanical strength combined with corrosion protection

- Aluminum option for areas where weight needs to be considered

- Great UV resistance

- Interior coating provides resistance to burn through; lower coefficient of friction

PVC CONDUIT

- Nonmetallic

- Made with PVC

- Installed/connected using liquid glue

Features/Benefits:

- Lightweight; combined with corrosion protection

- Great choice for underground burial

Using PVC coated conduit and PVC conduit together often offers the best installation for superior corrosion protection and cost effectiveness. For example, PVC encased in concrete for burial, combined with PVC coated elbows for stub-ups, gives the advantage of corrosion protection below ground and corrosion protection combined with mechanical strength and UV resistance above ground. A PVC adapter (threaded on one side) allows for a transition from non-threaded to threaded conduit. Plus, a PVC coated sealing locknut can be used to provide a sealing sleeve over the exposed threads, thus protecting the joint.