Plasti-Bond Conduit & Fittings – The Right Choice

Installation of subpar quality conduit can result in premature product and system failure, catastrophic damage and costly downtime. Plasti-Bond is the right choice for companies and industries where risk of corrosion to electrical raceway systems is high.

01. Premium Corrosion Protection

Lasts 10x Longer Than Other Brands

Plasti-Bond provides proven PVC coating performance and reliable longevity – at least 10x longer than other brands that do not carry an ETL PVC-001 verified listing.

Plasti-Bond PVC coated rigid and PVC Coated aluminum conduit and fittings are readily available in all trade sizes 1/2” through 6” and feature 40 mil PVC exterior coating and 2 mil urethane interior coating. Plus, Plasti-Bond is in compliance with the following standards: UL 6/UL 6A, NEMA RN-1, ANSI C80.1, ETL PVC-001, IEC IP69/UL Type 4X and UL 1203.

The comprehensive line of Plasti-Bond PVC coated conduit, fittings and accessories are manufactured and distributed by Robroy Industries – Texas, LLC, an ISO 9001 Certified Quality Management System Facility located in Gilmer, Texas.

The Plasti-Bond Difference

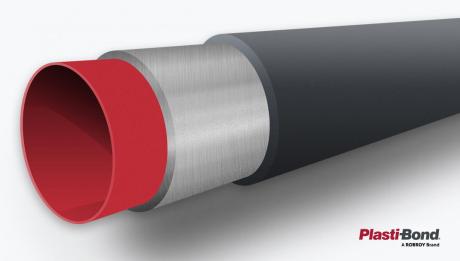

Plasti-Bond’s complete PVC coated rigid conduit system is at its best in demanding environments. We focus on points of vulnerability and then design our products for maximum protection. This is an inside look at how we do it.

Chemical Resistance

Withstands a wide range of corrosive chemicals to prevent exposure of metal to damaging environments.

Polyurethane Interior Coating

Uniquely formulated for optimum durability. Coating protects conduit interior from corrosion and chemicals and allows for friction-reduced ease of wire pulls.

UV-Stabilized PVC Formulation

Dramatically reduces UV degradation in outdoor applications. Formulation exclusively developed for Plasti-Bond.

PVC Gasket Seals

Protects the interior of the conduit system from corrosion by keeping corrosives from entering through assembled joints and openings.

PVC Coated Conduit Clamps

Coated pipe straps, clamps and clamp-back spacers designed for Plasti-Bond conduit and ease of installation.

Form 8 Condulet Cover Screws

Encapsulated stainless steel cover screws for Form 8 condulet are corrosion resistant and seal screw openings for maximum protection.

V-SEAL® Form 8 Fittings

Patented, unique interlocking V-groove along the cover edge effectively seals out corrosive elements from cover area and established a NEMA 4X/IP69 seal.

PVC Sealing Sleeves

Sized to fit tightly over assembled coated conduit to keep corrosive elements from the threaded joints.

Molded Ribbed Couplings

Offers enhanced gripping around couplings for faster and easier installation.

Factory Nipples & Elbows

Comprehensive sizes and configurations, including standard and special radius elbows, ready for quick shipment. Provides lower labor costs via faster installation.

Installer Certification

Certification program offered free of charge at convenient locations. Certification is earned through authorized instruction and passing examination for proper installation. Only installers with authorized credentials are officially certified to install Plasti-Bond’s top-quality products. Learn More.

Installation Tools

Readily available to ensure faster, easier and damage-free installation.

5-Year Plasti-Bond Warranty

Our five-year warranty provides additional peace of mind, even after completed installation by a certified installer.

02. Unmatched Safety & Performance

Verifying Protection

All PVC-coated galvanized rigid conduit is not created equal. Be sure to specify Plasti-Bond’s complete system of conduit and fittings for unmatched safety and corrosion protection performance.

There is a major difference when it comes to PVC-coated galvanized rigid and aluminum conduit – ETL verification. If your raceway conduits don’t carry an ETL verified label, those systems may be at risk for premature product failure.

All major PVC-coated conduit brands comply with standards for safety as established by UL 6, but only ETL PVC-001 validates coating performance. Plasti-Bond consistently earns its ETL PVC-001 label by successfully passing the stringent tests required for verification each quarter.

Enhanced Adhesive Bonding

Plasti-Bond prepares the zinc surface of conduit to enable a degree of coating adhesion not achieved by other manufacturers.

As one of the original authors of NEMA RN-1, we understand and exceed the voluntary guidelines of this standard.

For maximum bonding reliability, our unique Adhesion Enhancement Process (AEP) removes oxidation, white rust and contaminates from the outer surface. This prepares the surface for optimum adhesion without degrading it.

After PVC coating, trimming and final surface preparation, the clean pipe threads are hot-galvanized using specially designed 3-axis robotic arms to apply a consistent zinc protection. This process maintains the integrity of the threads.

03. Outperforms The Competition

Verifying Protection

PVC coatings are permeable and without a strong adhesive bond to a conduit’s steel substrate, the product will surely fail.

Loss of adhesion allows moisture inside the coating to create pockets, putting the metal in direct contact with corrosive elements. This limits the coated conduit’s lifespan and speeds up its failure.

Plasti-Bond’s PVC adhesive bond is proven to adhere and protect the substrate from corrosive damage and harsh environmental elements.

Seeing is Believing

Plasti-Bond and the competition both participated in a nationally recognized ASTM accelerated life-cycle test. Samples of each conduit were placed in boiling water for an equal amount of time. Afterwards, matching cuts were made in the PVC coatings. Then a tab was pulled with pliers to determine adhesive strength.

ASTM-Accepted Accelerated Pull Test Results

The competition’s adhesive bond failed and completely separated from the steel substrate. Plasti-Bond’s adhesive bond held and did not expose the substrate to corrosion. Disclaimer: All manufacturers pay for product testing or UL testing and listings.